Contact

For General Information:

Toll Free: (800) AJPOWER

Local: (813) 996-2583

Fax: (813) 996-5037

For Sales:

nigel at ajpower.com

For Engineering:

tad at ajpower.com

Updates from AJ Power

Capabilities

AJPS is in the business of providing custom and off the shelf solutions for high end power requirements, for both military and commercial markets. AJPS has been supplying high end custom power solutions directly to the US Navy, Air Force, Army, Marines, and Coast Guard for over 20 years. AJPS is also a veteran supplier of ground and airborne avionics power systems to prime contractors of the US Department of Defense, other US government agencies, and its allies. Among those prime contractors, AJPS is a long time supplier to Northrop Grumman, DRS, Harris, L3, Boeing and General Dynamics, having supplied thousands of power systems to these subcontractors. Regardless of quantities or product ordered, AJPS has always provided fast, reliable, and enthusiastic service to each and every customer during development, production, and follow-on support.

AJPS key competitive advantage is its ability to take its customer’s design concepts and power requirements to actual product quickly, efficiently and cost effectively. AJPS designs systems based solely on existing designs and power platforms to insure high reliability and short development time to our customers. AJPS is staffed by experienced power supply designers with over 100 years of combined power supply experience. All of AJPS’s operations are monitored and controlled by ISO 9001:2000 based quality system.

Analysis of your system requirements

Analysis of your system requirements

Our engineers at AJ's Power Source have over 100 years combined experience analyzing and designing power systems using standard power products from over forty manufacturers. We begin by learning our customer's markets and objectives and then develop specifications that clearly state which items are required and which are desirable - subject to space and cost restraints. For any power source, there may be more than fifty, performance, quality or cost parameters to analyze.

Conceptual Design

Conceptual Design

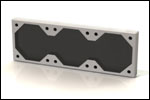

This is where our knowledge of power systems saves a customer many weeks of searching for the right components to build the end product, as well as thousands of dollars in design charges. This speeds up design of the power system, and simplifies UL approvals. Included in our conceptual design are preliminary layouts, schematics and data sheets for all of our standard modules used. Our proposals include: Pricing, NRE, Projected Schedule from design to production, and optional items recommended to save money or enhance performance. Rack mounted products or plug-in assemblies are designed to emphasize the customers color scheme and logo. We also adhere to all UL and customer labeling requirements.

Power Supply and Power Distribution

The custom power supply and power distribution market is fragmented with no manufacturer or style dominating the market. Each customer's power requirements depend on their unique combination of:

- Input Power Ranges (AC-DC)

- Single and Multiple Output Power Ranges

- Form Factors

and a variety of other specifications related to each specific design. The challenge is to select a standard power supply or combination of power supplies that meet the majority or all of the specifications required of our power unit. AJ's Power Source enhances and packages the selected products to achieve all of the customer's performance, quality and price objectives in a short turn around time.

Integration

Integration

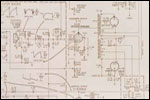

Our first step is to develop a schematic that incorporates the power supplies and all supporting circuits such as: regulators, fuses, switches, OR'ing diodes, current sharing components, connectors, filters, by-pass caps, monitoring circuits, control circuits, LED indicators, heatsinks, and any other possible electronic components in a power system. While the customer is reviewing the schematic, we design the mechanical chassis and assembly to fit each desired form factor and environmental qualification. The PCB is laid out with an interactive schematic capture program that assures that the layout matches the schematic, has no shorts and adheres to UL spacing requirements. The design phase usually will take 1-2 weeks.

Prototype Assembly and Test

Prototype Assembly and Test

In order to assure timely delivery, we order the power supplies, connectors and other known long-lead items before beginning design. With our long time in the Tampa market, we have devolved good relationships with the local manufacturers and representatives. This aids us in fast turn around on sampling product and reduced cost of production. After customer approval of the design, we prepare a parts and reference designator list, order the PCB, metal parts, and remaining components. We then complete the assembly diagrams and subject the prototype to stringent test procedures dependant upon what each customers requirements are for the specific design. These tests can be designated to adhere to many military standards including: Shock and vibe, Lightning, and Mil-STD-1275.

Testing and Confirmation by Customer

Testing and Confirmation by Customer

Upon completion of the prototype and shipment, we usually ship one unit to the customer and keep one unit at our facility to accumulate as many test hours on the system as possible before design freeze and production. If UL and/or Military approval is required, we forward one unit to the UL testing lab for processing and approval.

Production

Production

Production begins only after the customer has accepted the prototypes and all documentation has been updated and frozen. We use local fabricators, which are either MIL-STD and/or ISO qualified. It is our standard practice to complete all of the steps in 8 weeks - plus 6 weeks for safety approval.